Breaking news

HII & GDEB integrate 3D printing into shipbuilding process for Virginia class subs.

According to a PR published by HII on September 26, 2023, Newport News Shipbuilding Division, in collaboration with General Dynamics Electric Boat, has intensified its efforts to incorporate 3D printing into the shipbuilding process for nuclear-powered submarines.

Follow Navy Recognition on Google News at this link

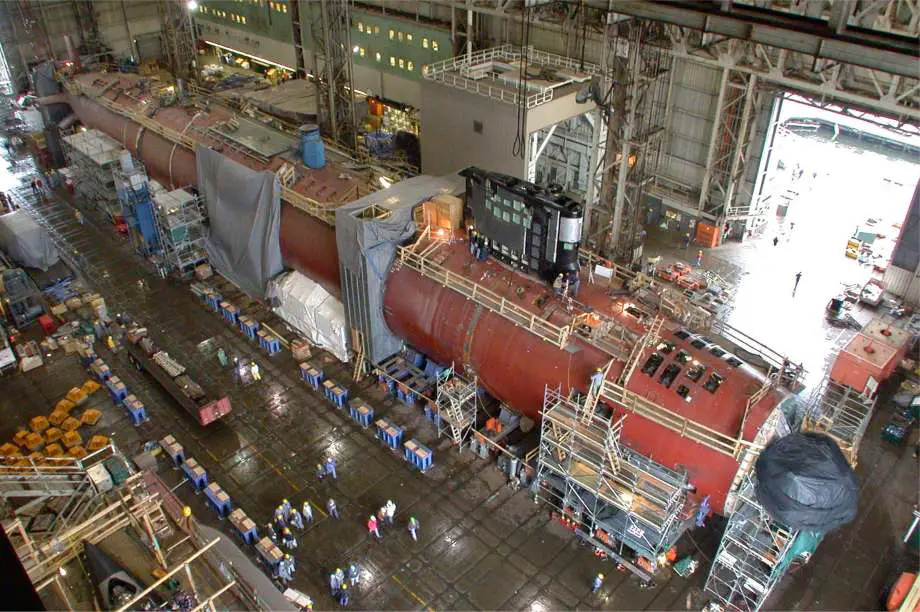

Virginia class submarine USS Virginia. (Picture source: US DoD)

Virginia class submarine USS Virginia. (Picture source: US DoD)

This move to use certified 3D-printed parts could potentially hasten the construction and subsequent delivery of submarines to the U.S. Navy by minimizing waiting periods for essential components.

The focus has been on introducing marine-based alloys, especially copper-nickel, as an alternative to the conventional castings. A recent milestone was reached when a copper-nickel deck drain assembly was developed using 3D printing.

After partnering with supplier AMMCON to refine the model and confirm its feasibility, a copper-nickel deck drain component was produced. This part is set to be incorporated into the Virginia-class submarine Oklahoma (SSN 802) after AMMCON completes the final machining and assembly.

This progress in 3D printing technology builds upon an earlier announcement that Newport News Shipbuilding has been certified as an approved vendor for 3D printed components on Naval Sea Systems platforms, a move expected to bring about cost and time savings in naval ship production.