Naval Surface Warfare Center Panama City Division (NSWC PCD) is developing another way to protect naval assets and Sailors at the pointy end of the spear.

Naval Surface Warfare Center Panama City Division (NSWC PCD) is developing another way to protect naval assets and Sailors at the pointy end of the spear.

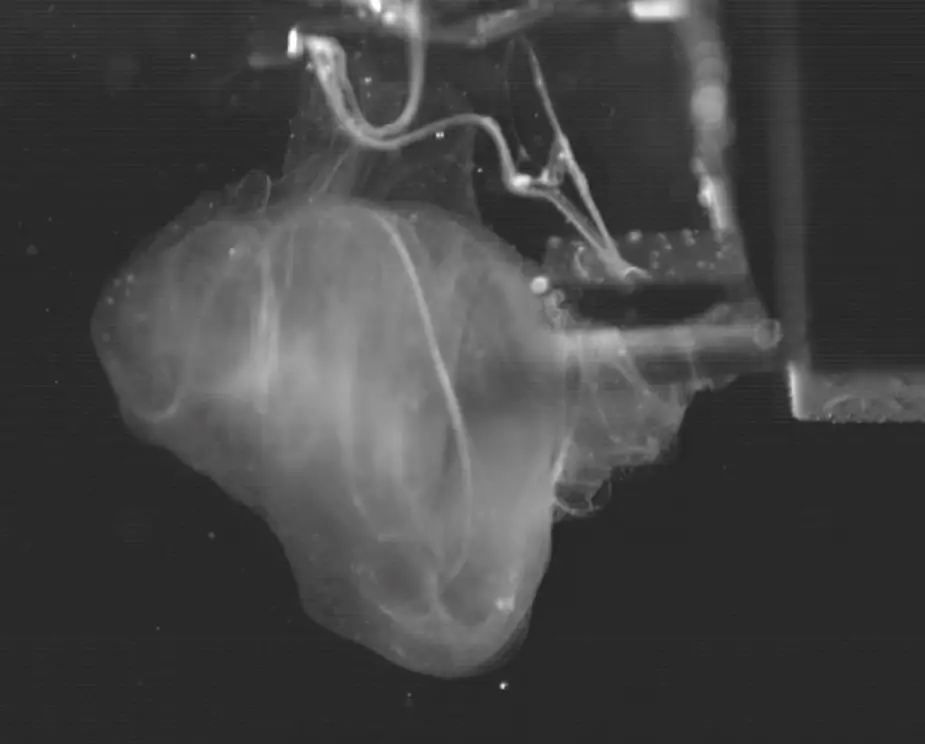

The Maritime Vessel Stopping Occlusion Technologies, or MVSOT, team at the Naval Surface Warfare Center Panama City Division investigates natural hagfish slime as an inspiration for a non-lethal capability (Picture source: Navsea )

The Maritime Vessel Stopping Occlusion Technologies, or MVSOT, team at the Naval Surface Warfare Center Panama City Division investigates natural hagfish slime as an inspiration for a non-lethal capability (Picture source: Navsea )

Maritime Vessel Stopping Occlusion Technologies, or MVSOT, is a promising non-lethal tool for the warfighter to significantly slow or stop an on-coming target vessel. The MVSOT team specifically focuses on technologies that limit or remove the ability of a propulsion system to provide thrust to a boat, but in a reversible manner.

“These technologies are persistent but reversible, allowing the warfighter increased standoff time and distance to de-escalate a potentially threatening situation,” said Dr. Michelle Kincer, NSWC PCD materials engineer. “MVSOT solutions may provide the warfighter a new capability for their toolkit which will allow them more time to ascertain the intent of an oncoming vessel.”

The MVSOT program is working with vendors to test commercially available drogue lines for a near term solution. These drogue lines utilize lengths of rope with sea anchors to restrict forward momentum of a target boat using drag forces. Testing to date has shown these products to be repeatable and reliable, although limited to only certain vessel types.

The program is developing next generation occlusion materials for a more all-in-one solution. These next generation materials include synthetic hagfish slime and spider silk proteins, which lend advanced swelling, adhesive, and strength properties not available in current commercial products. These materials are derived from natural products and will be more environmentally compatible.

“One of the common methods of occlusion is to utilize material to wrap around the propeller blades, allowing the propeller to continue to rotate but disrupting the blades from pushing any water and, thus, propelling the boat forward,” said Kincer.

NSWC PCD has recently collaborated with the University of Michigan, Utah State University, and Chapman University to characterize occlusion properties and produce synthetic hagfish slime intermediate filament proteins, and recreate the natural slime-like behavior.

Kincer said hagfish secrete a slime substance as a defense mechanism against predator fish, and the substance swells 10,000 times its original volume when it comes into contact with sea water. The resulting slime can be compared to a fiber-reinforced gel made of intermediate filaments, mucus, and seawater. This slime has shown to be persistent and effective at occluding propellers and intake systems.

“Looking at another material, spider silk rivals the strength of Kevlar and, on a weight comparison basis, steel,” said Kincer. “Our teammates at Utah State University have identified alternative uses of synthetic spider silk proteins which have many properties that non-lethal vessel stopping may benefit from, including robust sponges and underwater adhesives.”

As these next generation solutions develop, the MVSOT team looks to integrate the different materials in a total solution package and test in scaled test tanks as well as in-water at-sea testing.