Breaking news

ECA Group to supply steering consoles to HHI for the ROK Navy KSS-III Submarine.

| 2017

|

|

|||

| a | |||

|

Naval Industry News - France, South Korea

|

|||

|

|

|||

|

ECA Group to supply steering consoles to HHI for the ROK Navy KSS-III Submarine

|

|||

| Already providing steering consoles for 2 submarines as part of the Korean Jangbogo III (KSS-III) Batch I Submarine project, ECA Group has been entrusted with a supply of another steering console for the 3rd and last submarine of the first batch. | |||

|

|

|||

Steering console for KSS III. ECA picture. Steering console for KSS III. ECA picture. |

|||

|

|

|||

| The design of KSS-III Batch I and manufacturing of the two firsts submarines was attributed to the South Korean DSME shipyard which awarded early 2014, ECA Group for the design and manufacturing of the two firsts Steering Consoles. The manufacturing of the remaining third submarine has been attributed to Hyundai Heavy Industries shipyard which in turn, entrusted ECA Group for the supply of the third Steering Console. Thanks to this contract, ECA Group is now cooperating with a new customer, Hyundai Heavy Industries. Keel laying of the third KSS-III took place in June this year. Design and manufacturing of the firsts submarines of the second batch (called KSS-III Batch II), has already been attributed once again to DSME shipyard which enables ECA Group to be now in good position for participating to the new tender regarding the KSS-III Batch II Submarine programme. |

|

|

|||

|

Short video on KSS-III Batch 1

|

|||

|

|

|||

| Jangbogo III programme Under the Jangbogo III programme, the first submarine is due to be launched in 2018 and handed over to the ROK Navy at the end of 2020 following two years of sea trials. The second submarine will be delivered at the end of 2022. KSS-III is expected to be produced in three batches: Batch-I consists in the first two hulls to be built by DSME and the third submarine to be built by HHI. Batch-II will consist in three hulls with some design changes. They will be fitted with a greater deal of South Korean technology. In May 2016, DAPA selected DSME for “KSS-III Batch-II Design and construction of the first hull”. Batch-III will consists in the three remaining hulls (for a total of nine KSS-III submarines across all batches). The last submarine is expected to be delivered in 2029. The original design of the submarine includes 6x VLS (vertical launch system) tubes. They would accomodate a future cruise missile in development by LIG Nex1 while the launchers would be provided by Doosan (now Hanwha). It was announced earlier in the program that Spanish company INDRA was selected to provide its electronic defense system (ESM) PEGASO and Babcock of the UK would design and manufacture the Weapon Handling System for the Batch-I submarine. It was officialy announced during Euronaval 2014 that Sagem (now Safran Defense Electronics) would supply the optronic masts for the class. Flank array sonars will be provided by Korean company LIG Nex1. Hanwha Thales contacted Navy Recognition by email to explain they would supply KSS-III's combat management system. The submarine will be fitted with South Korean lithium-ion battery technology. |

|||

|

|

|||

KSS-III Batch I is a 3000 tons SSK submarine project fitted with 6x VLS (vertical launch systems) KSS-III Batch I is a 3000 tons SSK submarine project fitted with 6x VLS (vertical launch systems) |

|||

|

|

|||

| Detailed specifications of KSS-III (Jangbogo 3) Batch-I: Full-length 83.5m Beam 9.6m Pressure sensor diameter 7.7m Draught 7.62m Crew: 50 sailors Maximum speed: 20 knots Cruising range" 10,000 nm Surface tonnage: 3358 tons Submerged tonnage: 3705 tons KSS-III Batch II On April 25, 2016 there was a Congressional Hearing session held immediately after North Korea's SLBM launch, which raised some important questions about the ROK Navy's submarine capabilities to counter this threat. In response to questions whether ROK Navy was currently developing capabilities to counter SLBM threat, the ministry confirmed that KSS-III Batch-II will undergo redesign process before construction (lasting until December 30, 2018) to accommodate some important capability upgrades. These upgrades will give the Batch-II Submarines better capabilities at both attacking strategic land-based facilities and performing anti-submarine warfare. According to the recent DAPA statement, the Next Generation Submarine Project Team held a "System Functional Review" meeting on KSS-III Batch-II submarine in late June 2017. Through this meeting, the project team was able to confirm the design requirements for the Batch-II submarine under development are well reflected in the design. As a result, following the Batch-I, the Batch-II program has been promoted and the design has begun to materialize. Expected changes of Batch-II compared to Batch-I: » Lengthened hull (bringing displacement approx. from 3000t to 4000t) » Increase of VLS cells from 6 to 10 » Indigenous combat system and sensors » LiB and, potentially, High-Temperature Superconductor (HTS) motor for integrated full electric propulsion system |

|||

|

|

|||

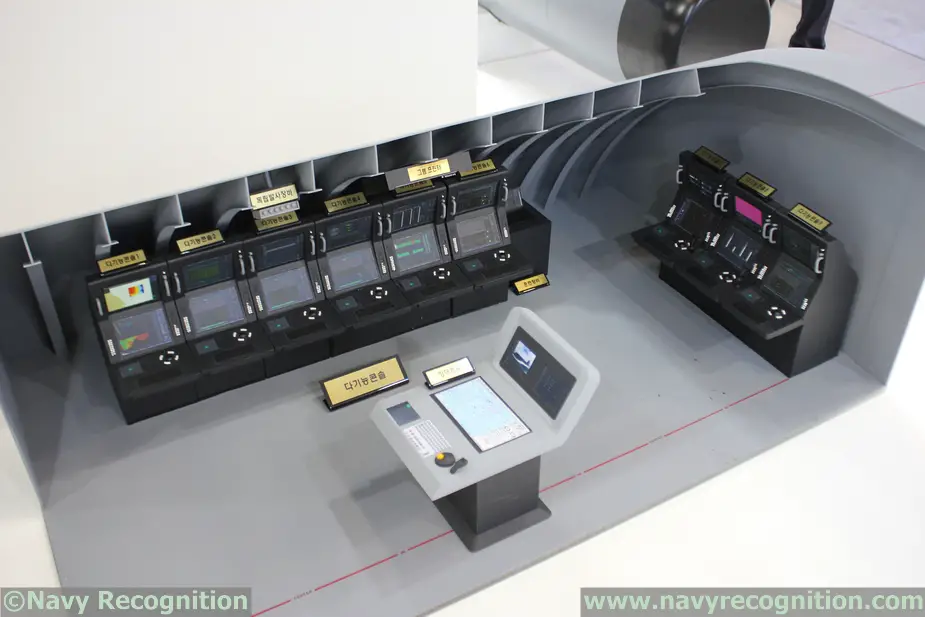

Scale model of the KSS-III Batch I operations room (on display on AAD stand at MADEX 2017 exhibition). Scale model of the KSS-III Batch I operations room (on display on AAD stand at MADEX 2017 exhibition). |

|||